SESAME Cooling system:

The electron beam at SESAME emits synchrotron radiation power of 60kW per 100mA that is dissipated into different parts in the machine and beamlines. Moreover, the power dissipated into the different magnet coils, RF cavities, and the corresponding power supplies is high also due to the high electric current and voltage used. Hence the cooling system which cools down such dissipated power is essential for protecting such equipment and bring them to thermal equilibrium case. The cooling system is responsible also for conditioning the air in the tunnels and experimental halls and keeping it at fixed temperature through the Air Handling Units (AHUs). The input cooling water used is kept at temperature 24 °C. The electrical conductivity of the water is reduced as much as possible by cleaning it from the different dissolved minerals and salts (producing what is called De-Ionized water) in order to make it safe at high electrical voltages. The cooling system consist of two main parts:

Production Side:

Two chillers that provide cooled water to the buffer tank to keep it between 9-11 °C and then distribute it for both heat exchangers and AHUs.

After the buffer tank we have two plate heat exchangers that exchange the water temperature between the cold side "chilled water" and the hot side "primary water circuit".

As part of the production side, we have a water treatment plant to produce De-Ionized water to feed it into the consumption side “primary and secondary circuits” or store it in the storage tank.

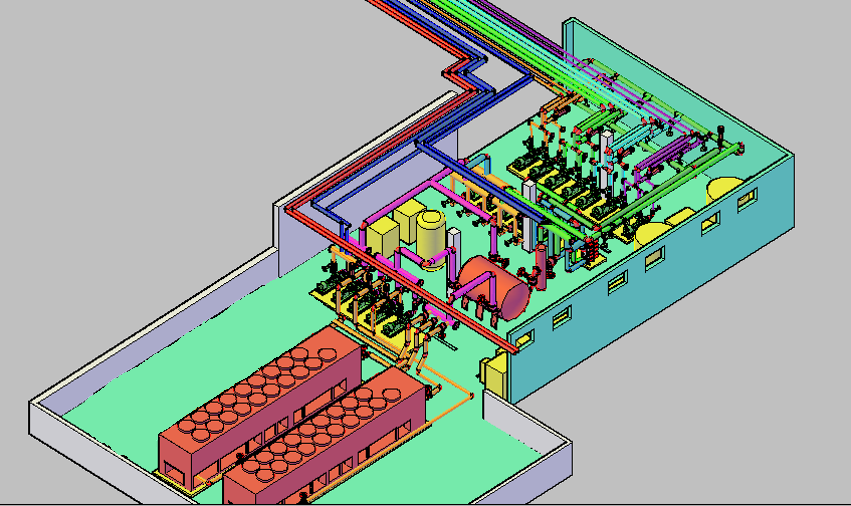

Figure 1. outline of the production side “technical building”

Consumption Side:

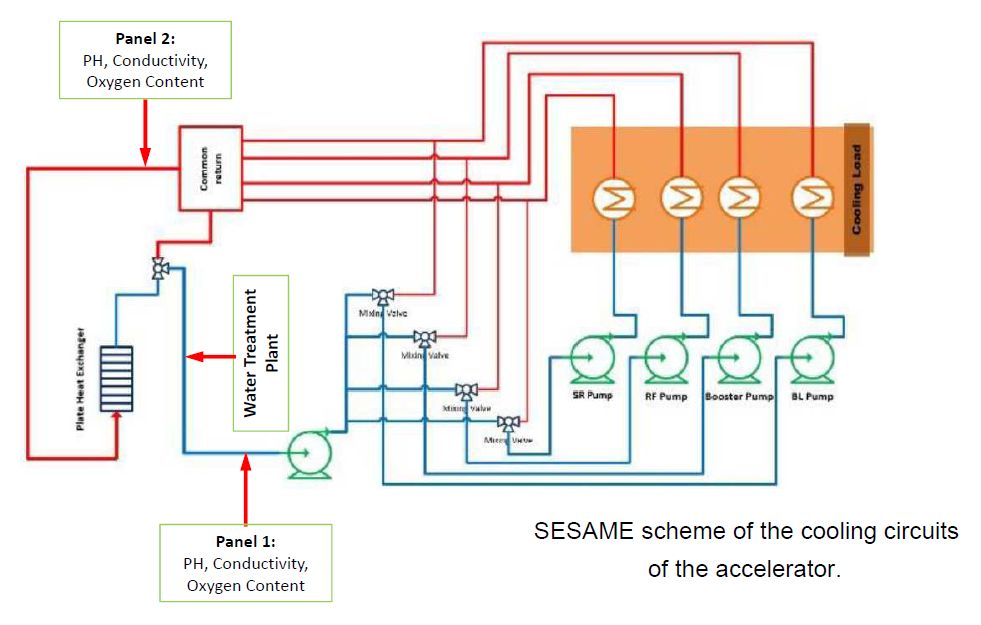

The consumption side consists of main primary stainless steel piping connected with heat exchangers to cool down the De-Ionized water and then distribute it to the secondary circuit which is composed of four circuits: Storage Ring (SR), Radio Frequency (RF) system, Beamlines (BL), and Booster Ring (BR), that is used to cool down the accelerator components. The primary and secondary circuits are closed circuits.

Cooling system main contents:

- One buffer tank, to store the cooled water from the chillers.

- Two Air Cooled Water Chillers, total capacity 2314 kW, that provide chilled water to the buffer tank.

- Two Plate Heat Exchangers, total capacity 1762 kW, that exchange the water temperature between the cold side "chilled water" and the hot side "De-Ionized water".

- Two Cast Iron Boilers, total capacity 252 kW, that provide hot water to the coils inside the AHU’s.

- Pumping System composed of 20 pumps.

- Two Air Handling Units outdoor “SESAME Roof”, Air Flow Rate 23500 L/s for each, that provide cooled, or heated and cleaned air to the Experimental Hall.

- Three Air Handling Units indoor, Air Flow Rate 1500 L/s for each, that provide cooled or heated and cleaned air to the Booster and Storage Ring tunnels.

- Two Compressors and two Dryers, providing pressurized dry air to the compressed air copper pipe circuit.

- De-Ionized Water Facility, that provides De-Ionized water to the primary and secondary circuits.

- Building Management System Hardware and Software, controlling and monitoring the whole cooling systems.

Mohamed AL NAJDAWI

Supervisor of Vacuum and Cooling Team

Email: mohammad.najdawi@sesame.org.jo

Work Tel: +962 5 351 1348 (Ext. 210)

Abdelqader YOUNIS

Cooling Engineer

Email: Abdalqader.younes@sesame.org.jo

Work Tel: +962 5 3511348 (Ext 217)

Osama NOUR

Principal Cooling Technician

Email: osama.nour@sesame.org.jo

Work Tel: +962 5 351 1348 (Ext. 232)