The mechanical engineering group operates s mechanical workshops that are used for prototyping and small series productions in conventional and high precision mechanics.

the workshop is led by a Workshop Supervisor.

Turning, milling, drilling, and grinding are all done both on conventional machines and also on CNC machine tools.

The following are the existing machines which are used to execute the function of SESAME mechanical workshop

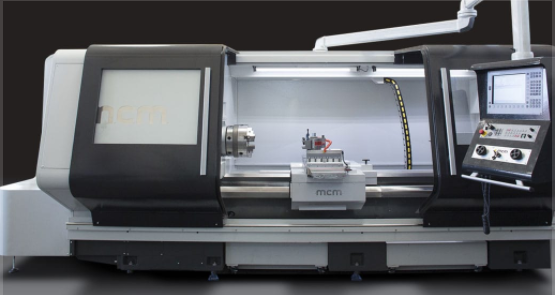

Turning Machine

CNC Turning Machine with standard Accessories Model ATL GIOTTO 280x2200x120 ,Distance between centers 1500 mm, center height 275 mm, with machine base and standard equipment, spindle speed step less from 0 - 2500 rpm.

Milling Machines

- MAHO MH600M 3 axis milling NC machine.

- HERMLE PF1000, HS78A. 3 axis milling NC machine.

Cutting Machines

- Air Plasma cutting and Gauging Machine Up to 22mm thickness

- BAND SAW (POWER HACK SAW) EXCEL BSA 280V AUTOMATIC HORIZONTAL BANDSAW

Welding

TIG welding, Miller Dynasty® 280

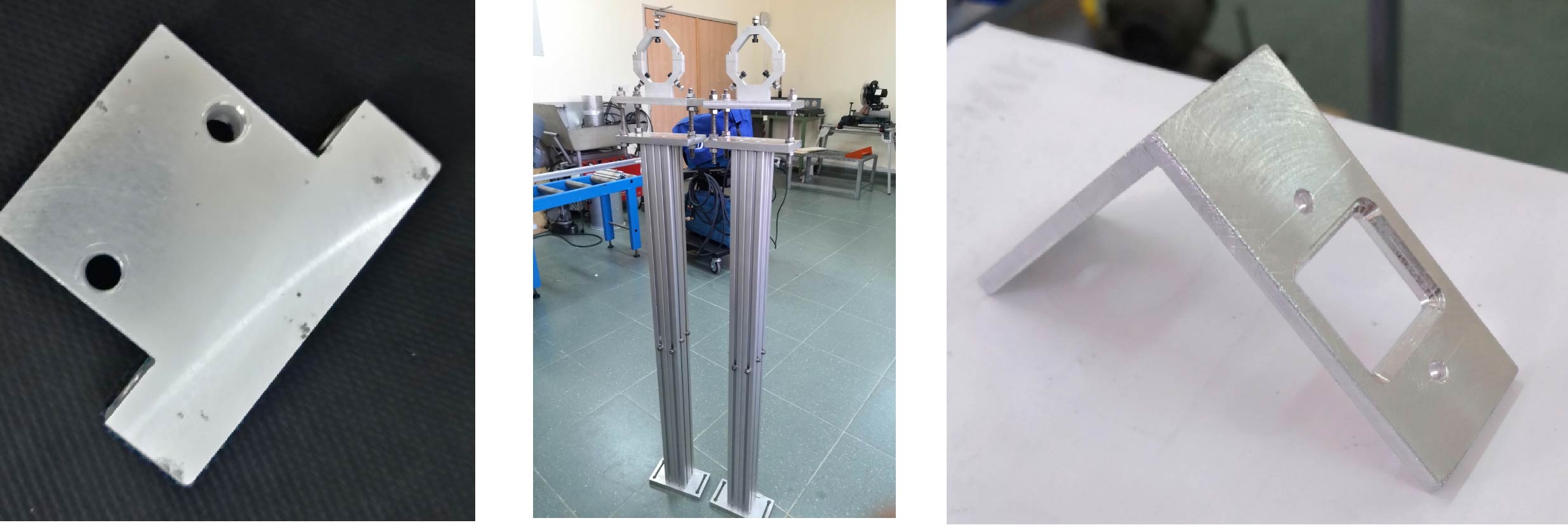

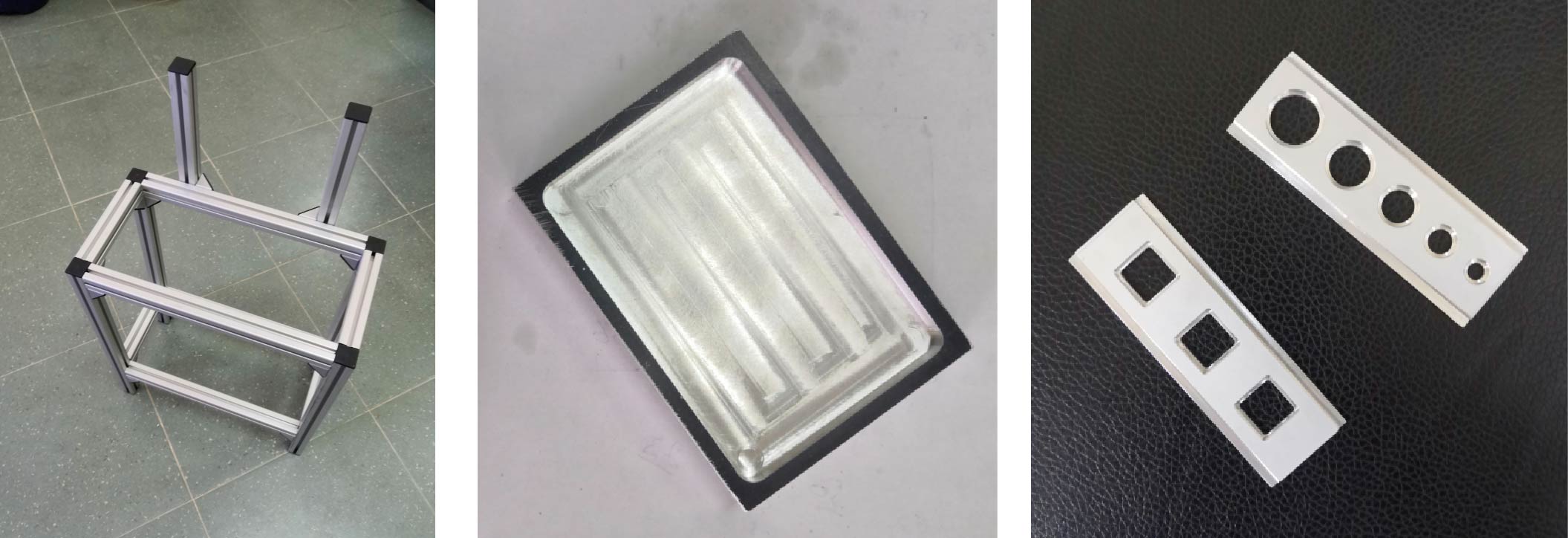

Samples of manufactured parts

Maher AL SHEHAB

Supervisor of Mechanical Engineering Team

Email: maher.shehab@sesame.org.jo

Work Tel: +962 5 351 1348 (Ext. 216)

Muhammad ALI

Mechanical Technician

Email: muhammad.iqbal@sesame.org.jo

Work Tel: +962 5 3511348 (Ext 236)

Abdel Rahman HASONEH

Mechanical Engineer (Survey and Alignment)

Email: abdelrahman.hasoneh@sesame.org.jo

Work Tel: +962 5 351 1348 (Ext. 237)