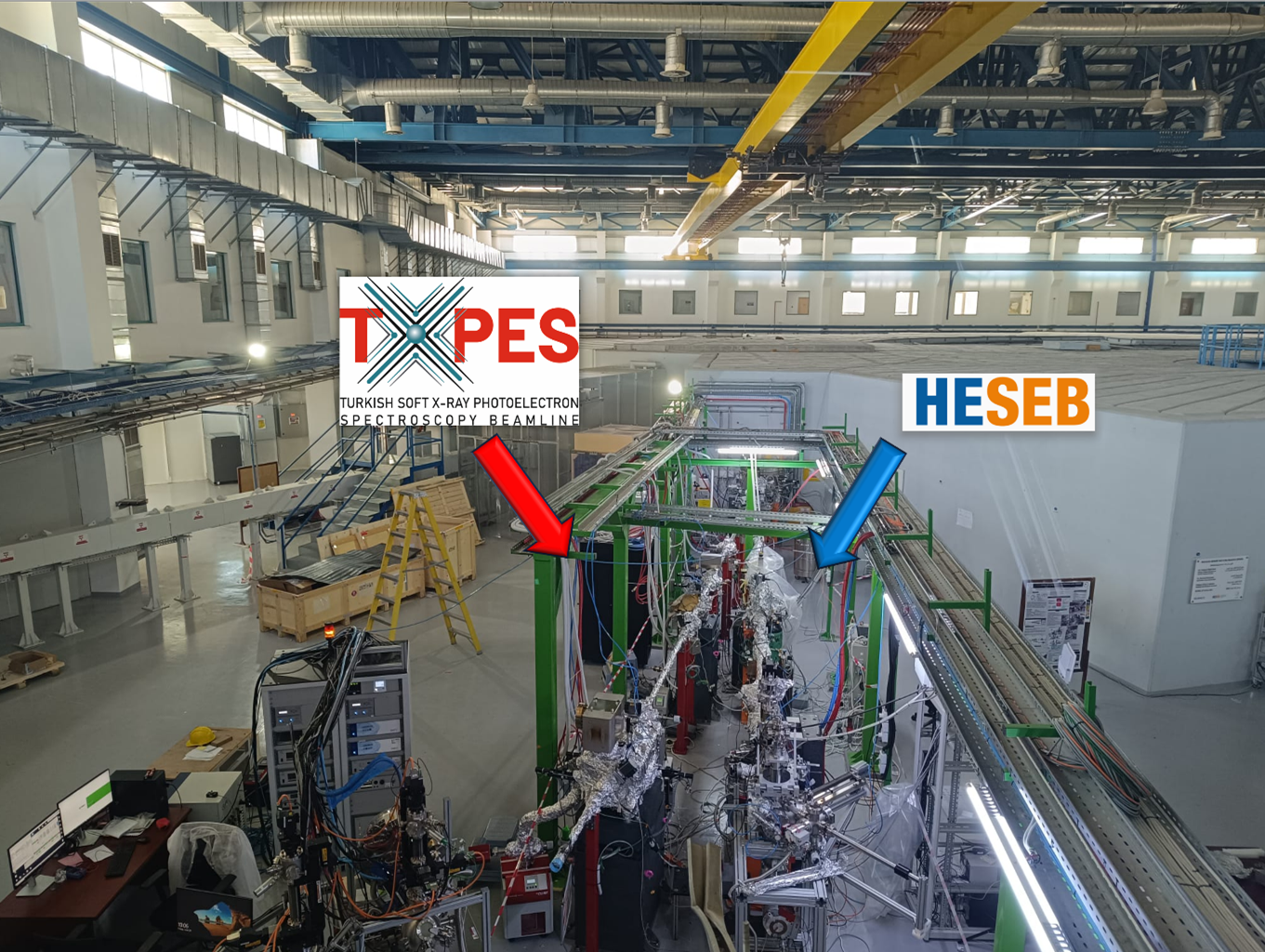

Figure. Beamline front view

Welcome to the TXPES (Turkish X-ray Photoelectron Spectroscopy) Beamline at SESAME

The TXPES (Turkish X-ray Photoelectron Spectroscopy) beamline at SESAME is a state-of-the-art research facility dedicated to high-resolution analysis of surfaces and materials. Building upon the existing HESEB beamline — which includes a dedicated branch for an additional end station — the TXPES beamline was developed under the leadership of the Turkish Energy, Nuclear, and Mineral Research Agency (TENMAK), in collaboration with Bilkent University, Koç University, and the Turkish Accelerator and Radiation Laboratory (TARLA).

This project represents a major milestone as SESAME’s first beamline fully designed, manufactured, and installed by Türkiye, one of the members of SESAME. Operating in the soft X-ray energy range (70–1800 eV), TXPES is tailored for the detailed characterization of nanomaterials, thin films, and catalytic systems. It provides valuable insights into surface chemistry, electronic structure, and interfacial phenomena, serving a wide range of research areas including materials science, catalysis, energy conversion, and thin-film technology.

Currently in its commissioning phase, TXPES is undergoing precise alignment, energy calibration, and end-station performance testing. The beamline is expected to open its first user call soon, and warmly welcomes collaborative and friendly users during this period.

As a sister beamline to HESEB, TXPES marks a significant expansion of SESAME’s capabilities in surface science and soft X-ray spectroscopy. It stands as a testament to strong instrumentation development and a forward-looking scientific vision, aimed at advancing collaborative research and enhancing regional expertise in photoelectron spectroscopy and materials characterization.

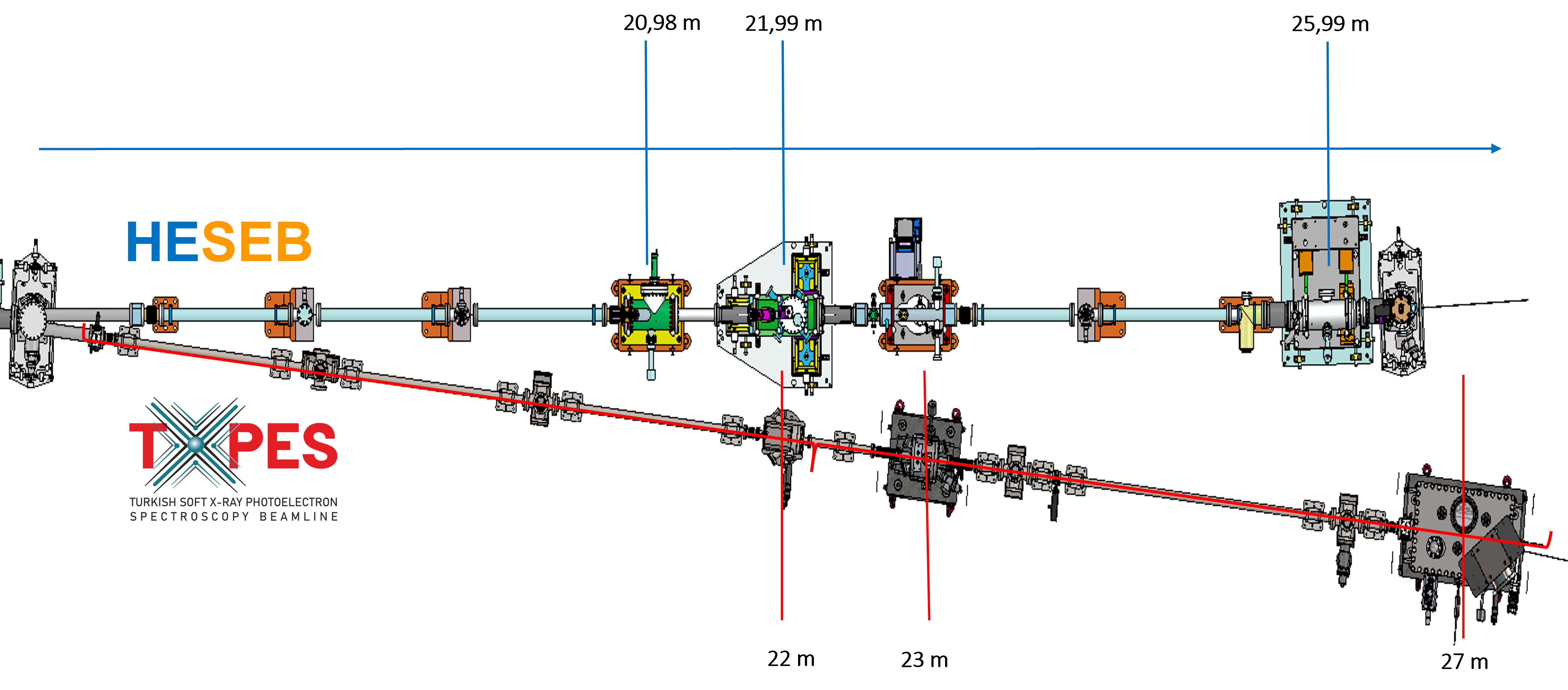

Figure. Beamline top view

INTRODUCTION

The TXPES beamline is designed with advanced optical components for precise beam control and high-resolution performance in surface and materials science experiments.

Figure. TXPES and HESEB Beamlines Schematic view

The TXPES beamline is designed as a sister beamline to HESEB, sharing the same Apple-II undulator source and plane grating monochromator (PGM) optics up to the M3 mirror. At M3, the photon beam is directed either to the left toward the HESEB end station or to the right toward the TXPES end station. Because the beam is steered to only one branch at a time, the two beamlines do not operate simultaneously, but instead receive the beam alternately depending on the selected configuration.

Beamline components:

- Photon Source: APPLE II undulator providing variable polarization (circular and linear) over 70–1800 eV, enabling the study of a broad range of elements and chemical states.

- Monochromator: Plane Grating Monochromator (PGM) optimized for high photon flux and energy resolution, allowing fine energy selection for detailed photoemission studies.

- Beam Splitter Unit (M3): Allows interchangeable operation between the TXPES and HESEB branches, ensuring efficient use of the photon beam.

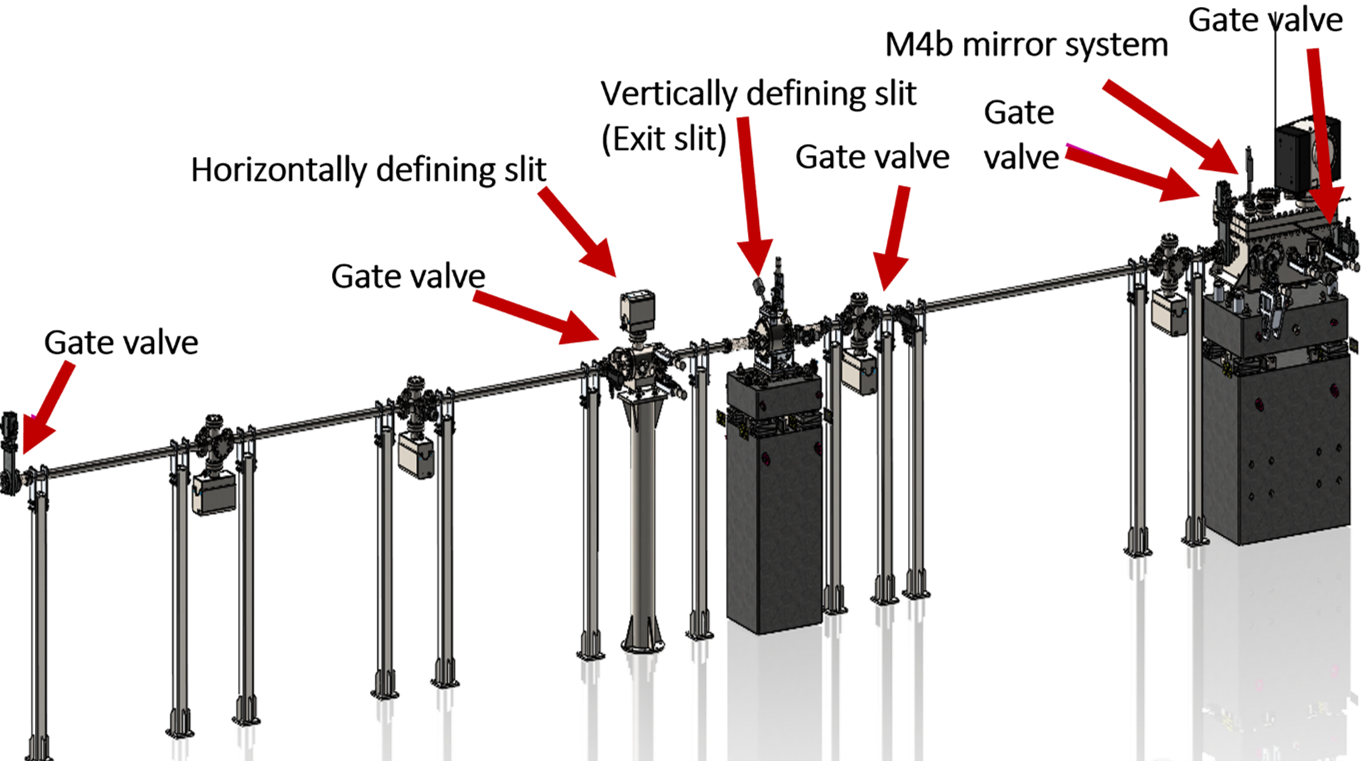

- Beam Conditioning System: Includes a Horizontally Defining Slit (HDS) with an integrated beam monitoring unit (YAG:Ce screen and CCD camera) for precise alignment and beam diagnostics.

- Energy Slit: Enables fine energy bandwidth control for high-resolution spectroscopy.

- Mirror System (M4b): Maintains beam collimation and focus stability across different experimental configurations.

Figure. TXPES Beamline optical branch Schematic view

This sophisticated optical setup ensures stable, tunable, and high-brightness illumination — a prerequisite for cutting-edge XPS, UPS, and LEIS investigations under ultra-high vacuum conditions.

End Station and Experimental Capabilities

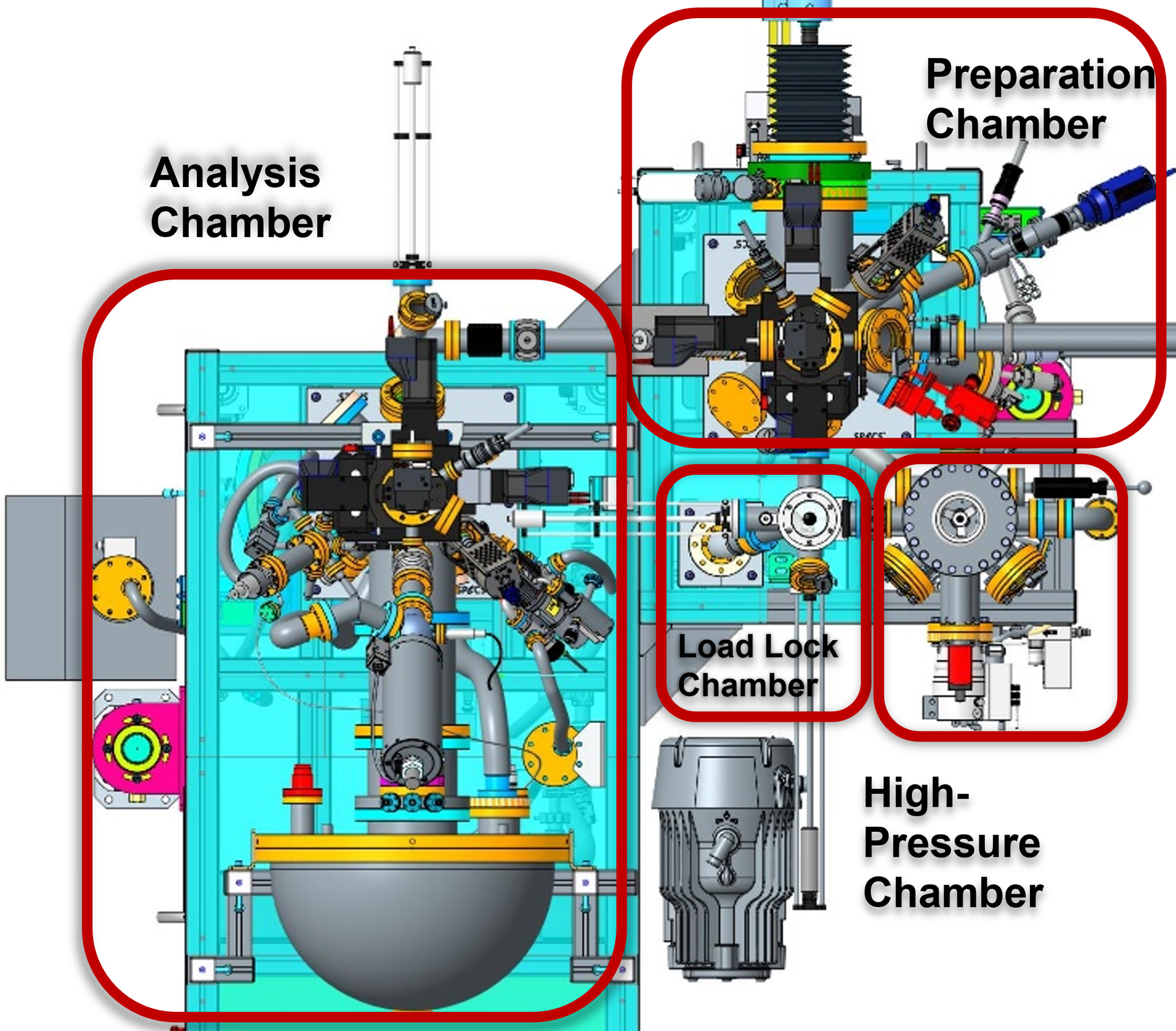

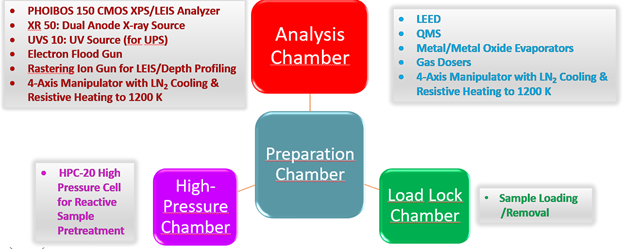

The end station of TXPES consists of three interconnected ultra-high vacuum chambers — Preparation, Analysis, and High-Pressure — linked by a Load Lock Chamber to preserve sample cleanliness during transfer.

Figure. TXPES End station schematic view

Figure. TXPES End Station Components: Chamber Modules

Load Lock Chamber:

Ensures rapid and contamination-free sample exchange while maintaining vacuum integrity below 10⁻⁹ Torr.

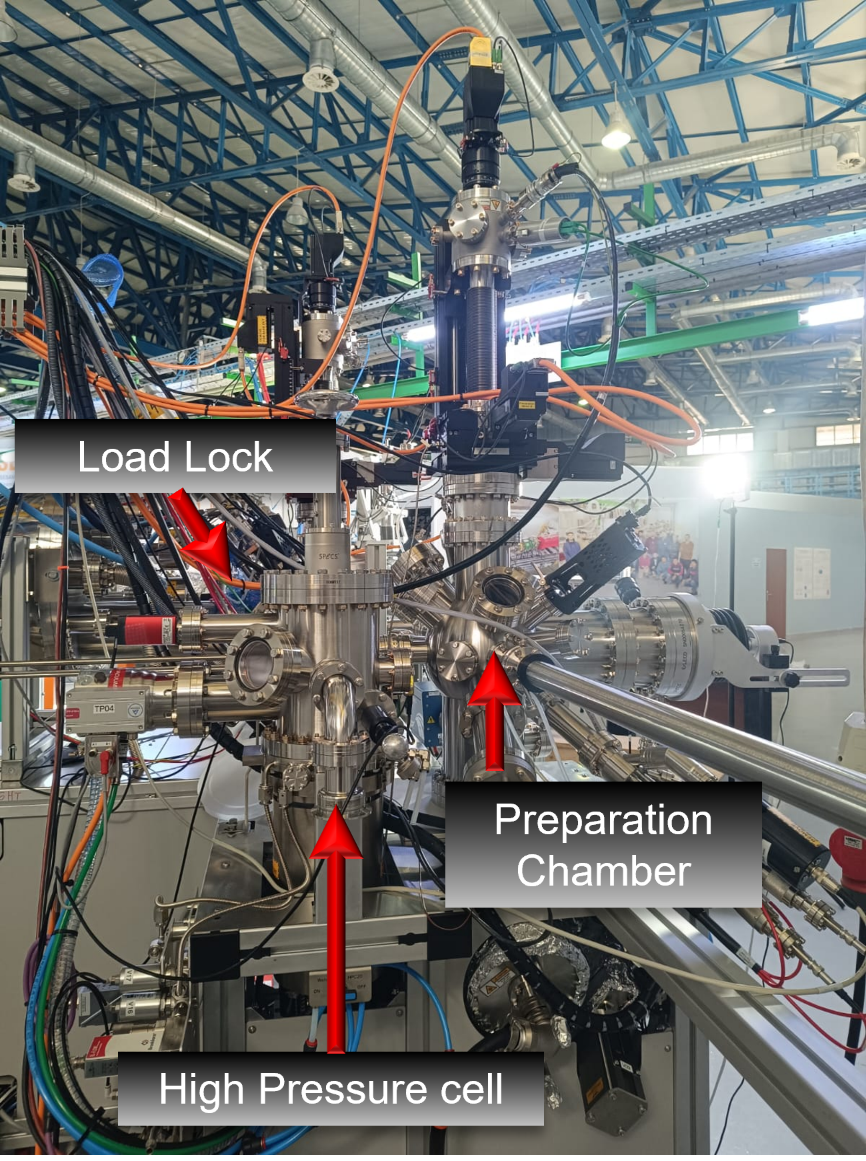

Figure. Load lock and High Pressure cell (HPC)

High-Pressure Chamber (HPC-20):

Designed for experiments under elevated pressures (up to tens of mbar) to simulate realistic catalytic and surface reaction environments. The high-pressure chamber (HPC-20) is a distinctive feature of the end station, designed to replicate real-world catalytic conditions by enabling sample treatments at elevated pressures and temperatures. It provides a controlled environment for reactive sample pretreatment, with capabilities extending up to 10 bar and 800 °C. This chamber is particularly suited for studies in catalysis and materials science, allowing for the investigation of gas-solid interactions under conditions that closely resemble operational environments. The HPC-20 thus facilitates a deeper understanding of catalytic processes and material behavior under high-pressure and high-temperature conditions.

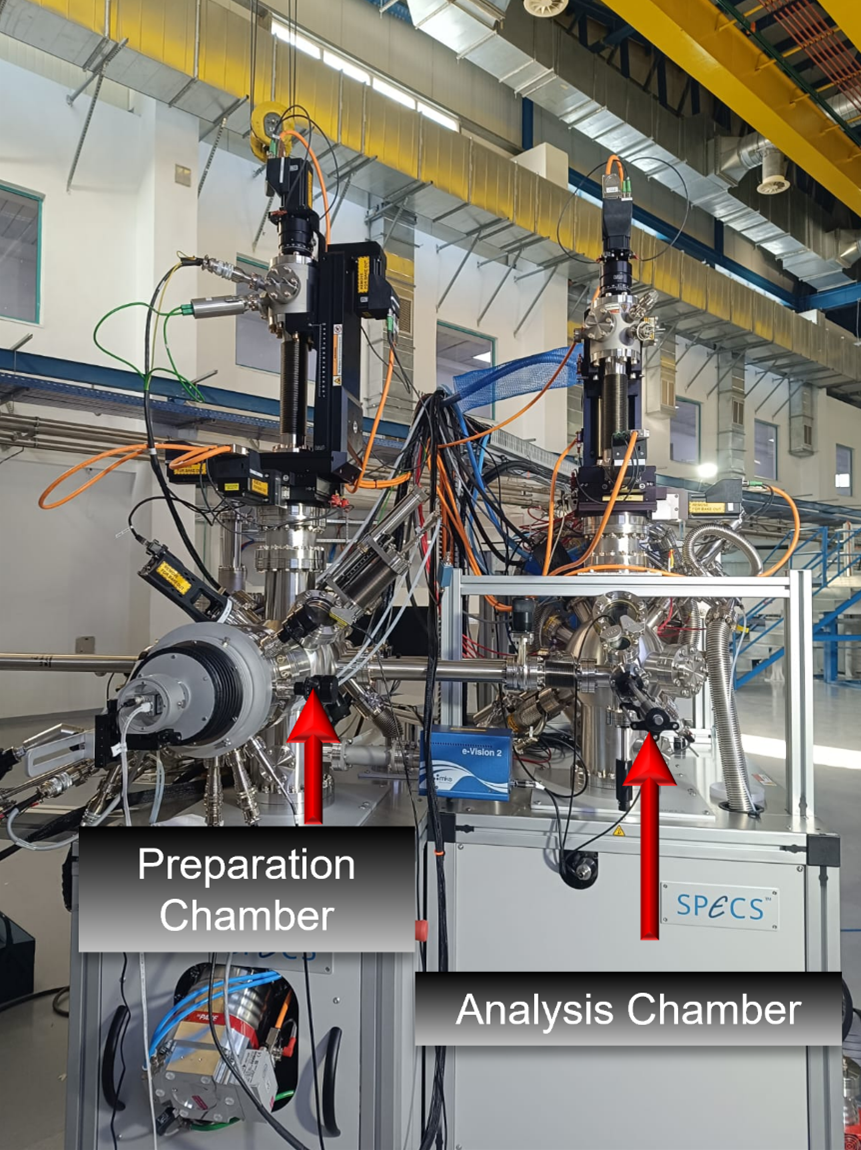

Preparation Chamber:

Figure. Preparation and analysis chamber

The preparation chamber is equipped with an extensive range of tools designed to support sample preparation and treatment processes. Low-Energy Electron Diffraction (LEED) is employed to analyze surface crystallography and structural characteristics, providing critical insights into surface reconstructions.

A Quadrupole Mass Spectrometer (QMS) is integrated into the system to perform residual gas analysis (RGA), which is essential for maintaining ultra-high vacuum (UHV) conditions by continuously monitoring gas levels and detecting potential leaks. Metal and metal oxide evaporators enable the deposition of thin films directly within the chamber, allowing precise control over material interfaces and detailed investigations into thin-film growth mechanisms. Gas dosers provide accurate delivery of reactive gases, making them indispensable for catalysis studies and examining surface reactions.

The chamber is also equipped with a 4-axis manipulator capable of liquid nitrogen cooling to temperatures below 100 K and e-beam heating up to 1200 K. This ensures precise control over sample temperature and positioning, enabling a wide variety of experimental setups to be conducted under optimal conditions.

Analysis Chamber:

Figure. Analysis chamber

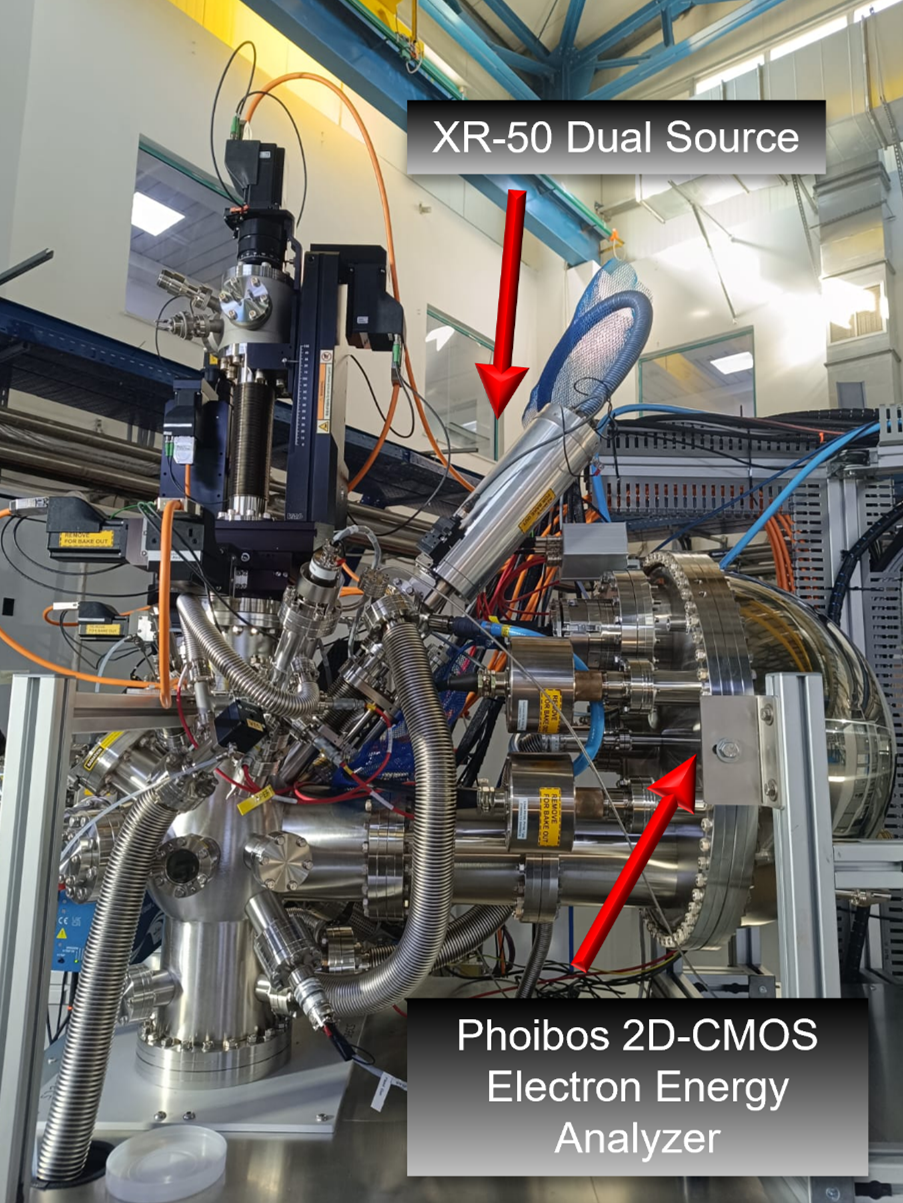

The Analysis Chamber is equipped with cutting-edge instrumentation for high-resolution surface and interface characterization. At its core, the PHOIBOS 150 CMOS Analyzer facilitates detailed chemical and electronic structure investigations using X-ray Photoelectron Spectroscopy (XPS), Ultraviolet Photoelectron Spectroscopy (UPS), and Low-Energy Ion Scattering (LEIS). This analyzer offers outstanding spatial and energy resolution, enabling precise determination of elemental composition and chemical states at the atomic scale.

The XR 50 Dual Anode X-ray Source provides a stable X-ray supply for XPS, ensuring continuity during maintenance periods when synchrotron radiation is unavailable, albeit with reduced resolution. For UPS, the UVS 10 ultraviolet (UV) source enables detailed studies of electronic structures, including valence band characterization and work function determination. In addition to XPS and UPS, the system supports Angle-Resolved Photoemission Spectroscopy (ARPES), which is critical for mapping electronic band structures. ARPES provides key insights into the dispersion relations of electrons in momentum space, offering a deep understanding of the electronic properties of advanced materials such as topological insulators, superconductors, and 2D materials. These capabilities are invaluable for unraveling the fundamental physics governing these complex systems.

To ensure measurement accuracy, an electron flood gun is employed to neutralize surface charging during XPS measurements, especially for insulating samples. The rastering ion gun enables precise LEIS analysis and XPS depth profiling, allowing controlled removal of surface layers for elemental composition analysis at varying depths.

The chamber also includes a 4-axis sample manipulator with liquid nitrogen cooling down to below 100 K and electron-beam heating up to 1200 K. This feature ensures precise sample positioning and temperature control, making it indispensable for temperature-dependent experiments, such as catalytic reaction studies, phase transitions, and other dynamic processes.

Scientific Applications

TXPES serves researchers in:

- Condensed matter physics

- Thin-film magnetism and spintronics

- Semiconductors and 2D materials

- Oxides and correlated materials

- Energy materials and catalysis

- Environmental science

- Cultural heritage and archaeological studies

- Surface chemistry and interface engineering

TXPES Capabilities

The TXPES beamline enables comprehensive surface and interface analysis through high-resolution X-ray Photoelectron Spectroscopy. Its capabilities include:

- Identification of all elements except hydrogen and helium

- Quantitative elemental composition analysis

- Empirical formula determination

- Chemical state identification

- Oxidation state determination

- Electronic state characterization

- Valence state analysis

- Precise binding energy measurements

- Depth profiling using controlled sputtering or photon-energy variation

- Elemental mapping for spatially resolved surface chemistry

Together, these systems enable researchers to conduct a wide range of surface and interface studies, from clean and controlled UHV experiments to operando and near-realistic conditions relevant to catalysis and advanced materials.

UE56 APPLE I I

UV 10 Ultraviolet Light Source

He I (21.2 eV, 58.4 nm), He II (40.8 eV, 30.4 nm)

XR50 Dual Anode Source-1

XR50 Dual Anode Source-2

Plane Grating Monochromator (PGM)

Horizontally Defining Slit (HDS)

M1

M3b

It allows switching between the HESEB and TXPES beamlines, ensuring flexibility in beamline operation.

M4b

Vertically Defining Slit (VDS)

Analysis Chamber

The XR 50 Dual Anode X-ray Source provides a stable X-ray supply for XPS, ensuring continuity during maintenance periods when synchrotron radiation is unavailable, albeit with reduced resolution. For UPS, the UVS 10 ultraviolet (UV) source enables detailed studies of electronic structures, including valence band characterization and work function determination. In addition to XPS and UPS, the system supports Angle-Resolved Photoemission Spectroscopy (ARPES), which is critical for mapping electronic band structures. ARPES provides key insights into the dispersion relations of electrons in momentum space, offering a deep understanding of the electronic properties of advanced materials such as topological insulators, superconductors, and 2D materials. These capabilities are invaluable for unraveling the fundamental physics governing these complex systems.

To ensure measurement accuracy, an electron flood gun is employed to neutralize surface charging during XPS measurements, especially for insulating samples. The rastering ion gun enables precise LEIS analysis and XPS depth profiling, allowing controlled removal of surface layers for elemental composition analysis at varying depths.

The chamber also includes a 4-axis sample manipulator with liquid nitrogen cooling down to below 100 K and electron-beam heating up to 1200 K. This feature ensures precise sample positioning and temperature control, making it indispensable for temperature-dependent experiments, such as catalytic reaction studies, phase transitions, and other dynamic processes.

Sample

Manipulator or Sample stage

Sample Environment

Sample Holders

High-Pressure Chamber

Sample

Load Lock Chamber

Sample

Preparation Chamber

A Quadrupole Mass Spectrometer (QMS) is integrated into the system to perform residual gas analysis (RGA), which is essential for maintaining ultra-high vacuum (UHV) conditions by continuously monitoring gas levels and detecting potential leaks. Metal and metal oxide evaporators enable the deposition of thin films directly within the chamber, allowing precise control over material interfaces and detailed investigations into thin-film growth mechanisms. Gas dosers provide accurate delivery of reactive gases, making them indispensable for catalysis studies and examining surface reactions.

The chamber is also equipped with a 4-axis manipulator capable of liquid nitrogen cooling to temperatures below 100 K and e-beam heating up to 1200 K. This ensures precise control over sample temperature and positioning, enabling a wide variety of experimental setups to be conducted under optimal conditions.

Sample

Manipulator or Sample stage

2D CMOS DETECTOR

counting. It consists of an MCP Chevron assembly with phosphorous screen and a fast camera

system with a high frame rate at full image resolution. Thus, it can handle large quantities

of event-style electron data.

Detection

SPECS PHOIBOS 150 Electron Energy Analyzer

Detection

Zeynep OZTURK

TXPES Beamline Scientist

Email: zeynep.ozturk@sesame.org.jo

Work Tel: +962 5 351 1348 (Ext. 348)