SESAME has installed a cutting-edge Programmable Logic Controller (PLC)-based system for controlling the cooling system of its accelerator in replacement of the Building Management System (BMS) that was in place, which presented a number of weaknesses, amongst which impossibility to be integrated with SESAME’s EPICS (Experimental Physics and Industrial Control System) machine control system. Six months on it is reaping the benefits of a more stable and efficient performance of its accelerator, a greatly reduced number of maintenance calls, and fewer interruptions to the users’ experiments.

This major upgrade to the cooling system was carried out by the Technical Sector in August 2024, and the new system is now fully integrated with the EPICS system, giving the machine operators a seamless control interface, and making it much easier to control the temperature in the accelerator and experiment areas. It was made possible thanks to the generous financial support from the Istituto Nazionale di Fisica Nucleare (INFN),.

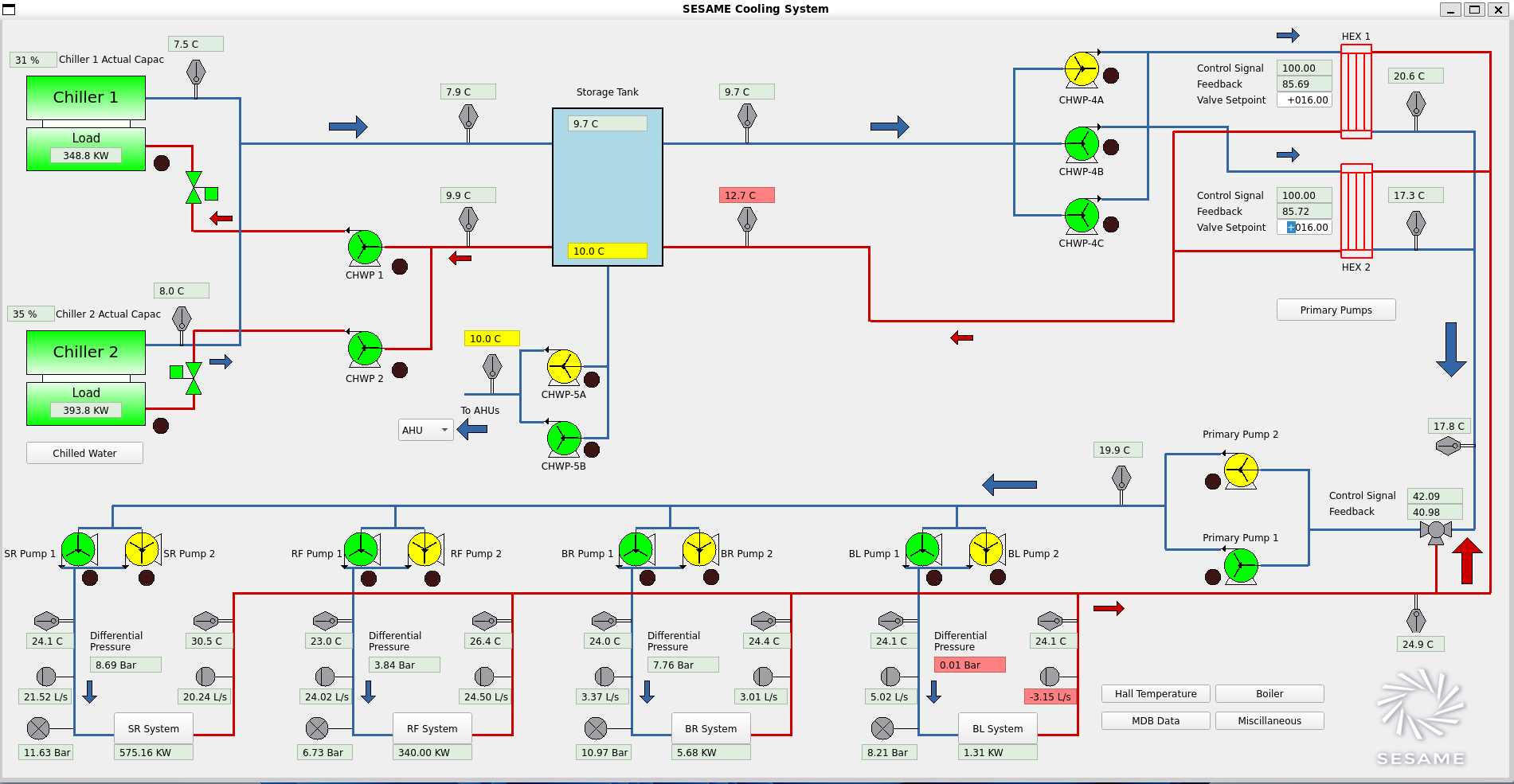

The cooling system circulates cooled water through various parts of the accelerator, ensuring that critical components stay within temperature limitations. It also controls the air temperature in the accelerator’s tunnel and in the experimental hall to ensure thermal stability of the machine and equipment. In other words, it is critical for preserving stability in the accelerator's temperature.

One of the most notable aspects of the upgrade was the implementation of a single Graphical User Interface (GUI), which centralizes monitoring of the different parameters, such as temperature, water pressure, and flow rates, making troubleshooting easier and generating real-time alerts and displays. It translates the PLC signals received from the different parts of the cooling system into a user-friendly display, simplifying parameter monitoring and control. This new interface fits the architecture of SESAME's other systems, thereby providing the machine operators with an intuitive and familiar working environment.

The new PLC-based system was created with future scalability in mind. Indeed, it allows SESAME’s control team to have full control over it, meaning that it is able to carry out maintenance works on it, to modify it to meet requirements whenever necessary, or to upgrade it, thereby assuring its long-term viability and enhancing the facility's ability to rapidly adapt to new issues. The control team has good experience in this new system.

“This upgrade constitutes a significant milestone for SESAME”, said the Technical Director, Maher Attal “as it not only improves the efficiency and reliability of our cooling system, and consequently of our machine, but also ensures that we are prepared for the future”. “The integration of the new PLC-based control system with EPICS is a game-changer, streamlining the cooling system’s operations and making it easier for our team to manage its complex processes”, he said. “We are very grateful for the support from INFN as this upgrade reinforces SESAME’s commitment to maintaining the highest standards in accelerator technology”, he added.

This upgrade marks a significant milestone for SESAME, strengthening the accelerator's infrastructure and propelling its goals to deliver state-of-the-art research. It will allow the SESAME machine to function more efficiently, reliably, and sustainably for the coming years.